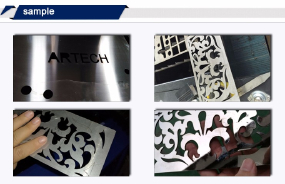

2016 Top Quality mini cnc fiber laser cutting machine for metal

Applicable materials and industry:

Industry: it's designed for metal sheet cutting and processing, such as plate processing, machinery manufacuring and precision processing, etc.

Materials: stainless steel, carbon steel, aluminum, brass and pipes, etc. Industry: it's designed for metal sheet cutting and processing, such as plate processing, machinery manufacuring and precision processing, etc.

Materials: stainless steel, carbon steel, aluminum, brass and pipes, etc.

Technical parameter:

1 | Machine Name | ART-1325F Fiber laser cutting machine |

2 | Laser machine cutting area | 1300x2500mm |

3 | Cutting thickness | 0.2-6mm stainless steel/0.2-12mm steel Option: 12mm Steel |

4 | Laser power | 500w option:300w/ 750w/1000W/1200W/2000w |

5 | laser device | Raycus option IPG |

6 | Laser wave length | 1080nm |

7 | Transmission system | Imported ball screw / Gear rack(optional) |

8 | X.Y axis location accuracy | ±0.01mm |

9 | X.Y axis repeat location accuracy | ±0.01mm |

10 | X.Y axis max moving speed | 30m/min |

11 | Max cutting speed | 1--16m/min |

12 | Min cutting line with | 0.02mm |

13 | Machine area size | 4.0x2.2x1.5m |

14 | Water chiller | Constant temperature water chiller |

15 | Controller | Friendiness |

16 | weight | 2500kgs |

17 | Red dot position | Yes |

Product Features

1. The double ball screw closedloop system and imported open CNC system enable high processing accuracy and high working efficiency during high speed cutting.

2. Standard collocation of 500W fiber laser generator and optional 400W-2000W fiber laser generator ensures low operation and maintenance cost.

3. Open structure is easy and convenient for material loading and unloading.

4. Aiming at high speed cutting, we design and manufacture strengthened welded machine body after 2 times of aging process which ensures long-term accuracy and stability of performance.

5. Standard collocation of dual-pressure gas control system of 3 gas sources (high pressure air, nitrogen, oxygen) meets the processing requirement of all kinds of materials.

6. Easy operation and low cost.

7. Optimized optical lens, specially designed nozzle and sensor technology realize smoother and more stable cutting.

Advantages:

1, High speed, high precision, high efficiency and low cost

2, Easy on operation, fiber optical path, without tediously adjustment on optical path

3, Compact structure, good sealing, strongly adaptable to changes in the environment.

4, With the perfect automatic nesting system which can save time, save the materials, the sheet utilization ratio up to 95%

Application insutry:

Aerospace technology, rocket, plane, robot, elevator, steamship and automobile manufacturing and metal parts processing industry for metal plate, advertisement, kitchen ware, bit tool, hardware etc.

ABOUT US:

Jinan Artech CNC MACHINERY Co., Ltd., established in 2006, specializing in CNC machinery with rich experience !The company has two factories: CNC Router and laser machine factories and plants.

Artech is comprehensive in the production, design, manufacturing, trade and service of CNC machine, and provide high quality and good efficient CNC machines worldwide. With a strong staff team, "Brand ArtechCNC" gained success in woodworking engraving machine, advertising engraving machine, stone engraving machine, metal engraving machine, laser engraving machine and laser cutting industry equipment. The production facilities occupies China's forefront in development and expansion.

Artech group integrates the excellent design, production and logistics resources, specialty engaged in the laser machine, engraving machine production and marketing job up to 11 years Now we have mature production workers more than 100 people, 10 sales teams, 2 product research and development teams , 2 after-sales service teams Products exported to Europe,America,Australia ,Africa,Asia etc, welcomed by consumers and good evaluation Artech people firmly believe that in the near future

FAQ:

Q1 For offer the most suitable machine,how should i do ?

1).The exact material you want to engrave/cut? (such as wood, acrylic, cloth, fabric, leather, metal.... ? )

2). For the Spindle Power, may I know the cutting or engraving depth you want?

3). The working area you demand? (such as max dimension of material, width*length,1200*1200mm,1300*2500mm,2000*3000mm, etc...

4). Do you want to engrave on planar &flat surface or round &curved surface?

If yes,the machine shall be added optional items, such as rotary attachment. if you can provide some pictures of your products,that would be great! after your tell us these,we will send you more information about the machine and price.

Q2.If we donot know how to use the machine,can you teach us?Yes,we will ,if you come to China,we will offer you free training until you can use machine freely.And if you are busy ,we will have the special engineer to your country,but you need to bear some fee, like tickets and hotel and meal.

Q3.How about your after-sales service?

we offer you 24 hours service phone,skype or MSN.

Q4.How about your guarantee period?

one year and during the time,if you have any questions ,we will solve it for free.